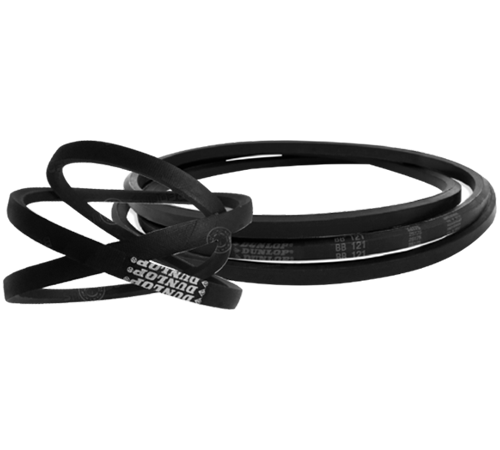

TIMING BELT

Timing belts are designed to link two or more rotating shafts. They offer high efficiency, high misalignment tolerance, economical and virtually maintenance-free, therefore, can be used to drive and control moving component parts in automotive, industrial, and agricultural applications.

Wrapped Timing belts remain the most widely used belt system in service today. They enable the use of smaller pulley diameters and so save costs on drive design.

Construction

Classical cross-section.

Arched top, concave sidewalls and rounded corners provide uniform tensile loading and uniform pulley sidewall contact for excellent belt service life and reduced pulley wear.

Oil and heat-resistant cover protects the belt core from the toughest environments.

The vulcanised tensile cords provide superior resistance to tensile and flexing forces, fatigue, and shock loads.

High-quality rubber compound protects the belt against heat, ozone, and sunlight.

The belt will not catch fire from heat build-up, even with severe slippage.

Advantages

Excellent performance/cost ratio.

Reliability and efficiency.

Long belt life reducing replacement and maintenance costs.